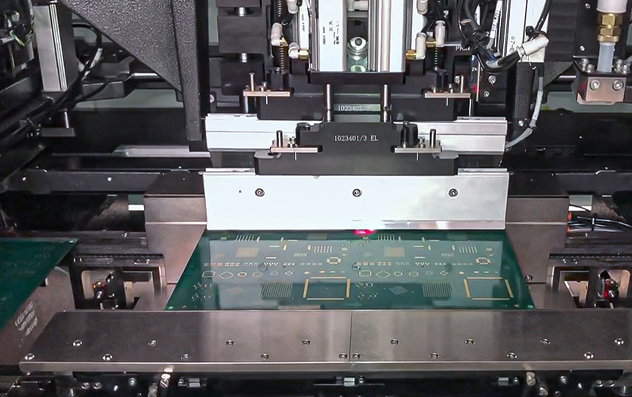

The MPM Edison II ACT (Automated Changeover Technology) was developed based on the proven MPM Edison platform, the industry’s most accurate printer with advanced technology. With a built-in ±8 micron machine alignment, and ±15 micron wet print accuracy (≥2 Cpk @ 6 sigma, Edison’s wet print accuracy. The Edison II ACT has a proven process capability greater than 2Cpk for 0201 metric components, an ideal solution to meet the increasing miniaturization and board component density challenges in Semiconductor, Automotive, Smart Devices and etc.

Production line changeover is one of the most labor intensive, time consuming, and error prone tasks in the electronics manufacturing. This innovative MPM patented Automated Changeover Technology (ACT) provides a simple, cost-effective and progressive solution toward the end goal for factory automation.

Faster Throughput for a Better Process

Edison’s new parallel processing system is extremely fast resulting in a very short cycle time. This helps increase throughput by shortening total time per PCB printed. This leaves more time for key overhead functions that have the biggest impact on print quality:

– Print at slower speeds to decrease variability

– Utilize slow stencil separation for optimal print definition

– Double stroke after wipe

– More frequent wiping resulting in higher yields

– Time leftover to optimize settings for maximum possible yields Incomparable Wet Print Accuracye=”font-weight: 300;”>Best-in-class printing with a 25% improvement in wet print accuracy over current printers: Built-in +/- 8 micron alignment, and +/- 15 micron wet print repeatability (≥2 Cpk @ 6σ) proven through 3rd party Print Capability Analysis (PCA) testing.

Back To Back (BTB) Configurable

BTB is a flexible dual lane solution without adding line length; identical single-lane printers are easily re-deployed to other lines when needed. Use in BTB configuration, or singly as a stand-alone.

Intueri Graphical User Interface

MPM Intueri is a simple, intuitive operator interface with a flexible, wide array of configuration variables. It is combined with OpenApps for maximum capability and connectivity and provides a portal to Industry 4.0 concepts.

Advanced Print Head

Single-axis, closed-loop pressure control for dual squeegee eliminates front-to-back variation. A single high-precision load cell provides squeegee force, and a unique algorithm calibrates out non-linearity, maintainng the set pressure across the entire board surface.

Ability to have three boards in the machine simultaneously, reduced distance on input conveyor by pre-loading the board during the print process results in reduced transfer times and improved cycle time.

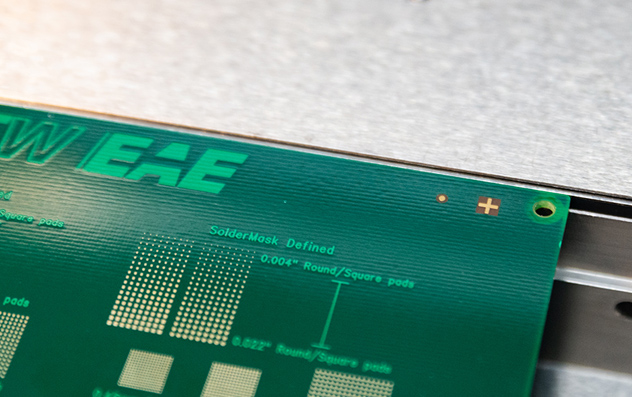

EdgeLoc Board Clamping

The EdgeLoc system uses a side snugging technique that removes the need for top clamps which interfere with the PCB to stencil contact. The result is optimal gasketing and more volumetrically consistent edge-to-edge prints. With EdgeLoc II, robust flippers engage to secure the board across the top edge ensuring board flatness then move out of the way once the board is firmly gripped from the side. EdgeLoc+ board clamping can change between edge and top clamping simply through software.

High Speed Vision Alignment with Ultra-slim Camera

Edison features a high-speed vision alignment system with an ultra-thin camera. The overall gantry thickness is only 39 mm featuring an ‘on the fly’ ‘POE’ (Power Over Ethernet) camera. A single CCD split field provides precision simultaneous up-down image acquisition with a field of view 9.0 x 6.0 mm.

OpenApps Architecture

OpenApps is an MPM open architecture source code that allows customers and third parties to develop custom interfaces in support of Industry 4.0 initiatives and Manufacturing Execution Systems (MES).

Paste Height Monitor

The Paste Height Monitor is designed to prevent defects caused by inadequate volumes of paste on the stencil. It combines advanced software and sensor technology to accurately monitor the paste bead for volume consistency. Upper and lower limit roll-height monitoring eliminates insufficient or excess paste volumes. It is a non-contact solution that can automatically add more paste to the stencil as it is needed.

SPI Print Optimizer

The SPI print optimizer communicates with the external Solder Paste Inspection (SPI) system to continuously monitor and auto-correct X, Y, and Theta registration ‘on the fly’ to stay on target and prevent print defects.

Ultra-fast, High Efficiency Wiping System

A super-size 65m paper roll allows 10,000 prints per change. Patented paper tension control provides more effective wiping and a separate wiping and printing zone prevents cross contamination.